Technical Information for Hydraulic Filters

The reason of 70-80% of breakdowns in hydraulic systems and 50% of breakdowns in bearings are wear and damages caused by polluting particle in the hydraulic fluid and greasing oil. For the hydraulic elements function completely, there are tolerances between moving parts. The hydraulic oil goes into these gaps and functions for impermeability. The polluting particles entering these gaps causes breakdowns and wears in components, hence the hydraulic system elements becomes unfunctional. Hydraulic oil is polluted with solid particles, liquid particles and gases.

Solid pollutants: Sand, welding slag, fibre, sawdust, rust, gasket residues, dye

Liquid pollutants: Water, liquids composed of different oil mixture.

Gas pollutants: Air

The Effects of Pollutant Subjects to System and Components:

Solid particles:

-Increase of leakages

-Jamming of valves, slide bars and pistons

-Component breakdowns

-Variations in control characteristics

Liquid particle:

-Corrosion

-Decrease of dynamic viscosity, ruptures in oil film, friction on surfaces, decrease in the lifetime of oil

-Change of oil characteristics, material production causing the aging of oil, mud formation

Gas particles:

-Cavitation

-Extreme local heating in oil

-Aging of the oil

-Unstable movements in the system, difficulty in control

-Decrease in the dynamic greasing film

The hydraulic filters are designed to work in extraordinary conditions and by dynamic change of oil in high pressure. Because they are mostly used in mechanisms and devices working in tough conditions. During their lifetime, they ensure the continuity of high performance by separating the dirt oils. The reliability of a hydraulic system depends mostly on the quality of the oil used and reliability of each element (pump, server motor, oil filling rate, condition of valves).

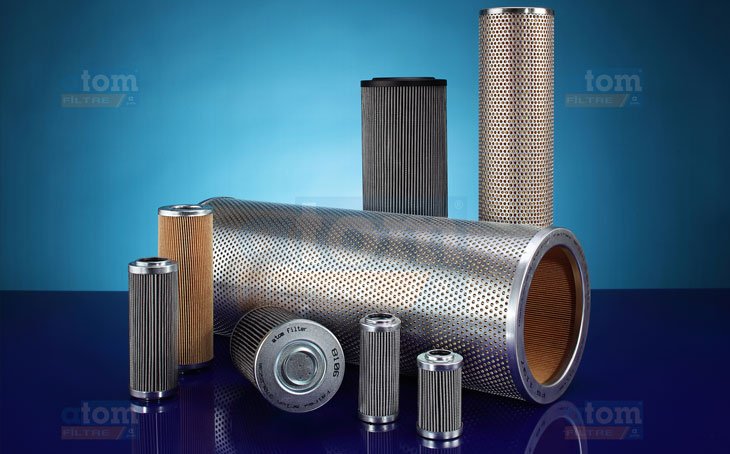

Filter Elements

a) Superficial Filters: In superficial filters, separation of particles occurs directly on the surface of the filter element. Small scale particles can get into the filter element without meeting any resistance. But as the surface gets clogged, the resistance of the filter increases. The particle layer formed on the filter surface increases the filtration degree. In superficial filtration, membrane filters of wired, metal cornered or metal saran filters are used. Superficial filters are composed of a single layer and produced from metal or paper. As they do not ensure a precise filtration, they are preferred in absorbtion filters.

b) Deep Filters: The fluid to be cleaned passed through the filter structure. The dust particles are collected in deep layers of the filter. As the collected dirt level increase, the resistance to flow increases too and the filter element should be replaced. Deep filters are composed of many layers. They are produced from glass fiber, cellulosic materil and sintered metal fibers. By means of their high dirt collection capacity and precise filtration ability they are used in pressure, rotary and circulation filters.

A good quality filter should have the following characteristics:

-Resistance to pressure variation

- ß stability for a wide pressure range

-Filtration power for all cleaning degrees

-Good dust collection capacity

-Large filter areas

-Long life

Filters are used mainly in 5 points in hydraulic system.

1) Suction line

2) Pressure line

3) Return line

4) Cooling and filtration circuit

5) Ventilation caps

Hydraulic filtration systems are divided into the following groups:

Full Flow Systems: In this system, the filter is mounted on the device (system) and it is ensured that all oil directly passes though the filter. For safety reasons, safety valves should be mounted to these systems. This valve can be at inner or outer part of the filter.

Half (Partial) Flow Systems: In these systems, filter is not directly but as parallel to the system. Because of this only a portion of the oils passes through the filter. As these systems are not efficient enough, they are not recommended.

Combined Filtration Systems: It is a system that shows characteristics of both systems. This system guarantees the best cleaning of the oils.

According to their structural characteristics, hydraulic filters are divided into a few types.

Strainer Type Filters: This type of filters are made of tight knit metallic fibers. They can only stop big sized particles in the filtration process, hence they are low efficiency filters. The only advantage of them is that they can be used for several times after they are washed.

Slit Filters: They are filters made of tight knit metallic fibers and put into asphalt (tar). They have a better filtration capability compared to strainer type filters.

Bulk filters: These filters are less frequently used in hydraulic systems because of their high strength and low efficiency and are accepted to be half (partial) flow filters. These filters are made of unwoven fabrics and loose their filtration (cleaning) property and only used to take the humidity.

Superficial Filters: They are made of pleated materials like paper or unwoven fabric (tissue). Steel strains are frequently mounted on these filters. As they have a very good filtration capability and mechanical strength, they are the most common used filters in hydraulic systems.

Bununla birlikte, tüm dünyadaki insanların zihninde spor ve uyuşturucu oynuyor. Örneğin Xylocaine, vücudunuzun bir bölgesinde hissizlik yaratır. Doğumdan önce verilir. Ayrıca acil kalp problemlerini de inceler. Erkeklerde cinsel işlev bozukluğunun genel bir formu erektil disfonksiyondur. Yazımız "Erektil Disfonksiyon" üzerine odaklanmaktadır. "Türkiye viagra" hakkında düşünmeniz gereken en önemli bilgilerin hangisidir? Birçok eczane onu "Ereksiyon Olamıyor Musunuz" olarak anlatılmaktadır. Ancak cinsel sağlığı ile ilgili pek çok sorun çözülebilir. Ve haplar genellikle çok güvenli kabul hoşgeldiniz. Sık görülen yan etkiler arasında mavi görme kutu, ancak tavsiye etiketlendi miktardan daha fazla almanız kesinlikle daha yaygındır. Bu ilaca bağlı olabileceğini düşündüğünüz istenmeyen etkilerle karşılaşırsanız, cinsel terapistinizle konuşun.

AFD FILTRATION

|

ADRES |

: Ay Yıldız San.Sit. 1126.Sk. No:9 Ostim |

| TEL | : +90 (312) 367 06 20 |

| FAX | : +90 (312) 367 06 02 |

| : info@atomfilter.com |